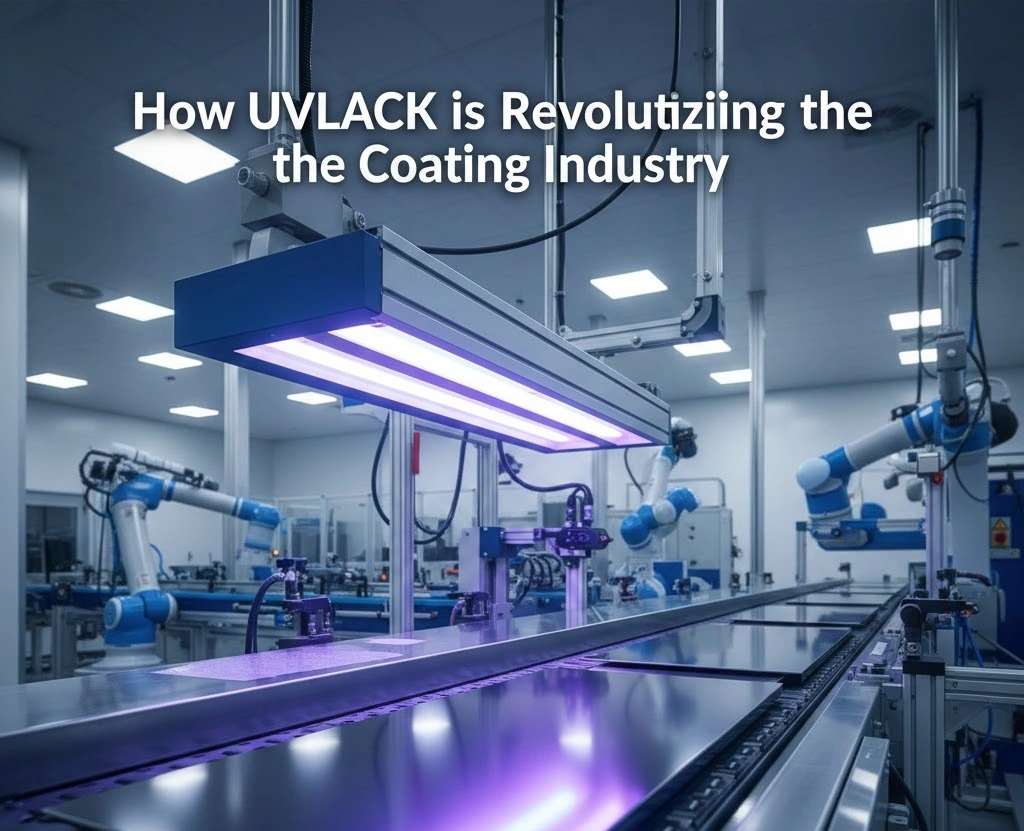

The first thing that catches your attention when you enter a modern manufacturing facility is the change. Waiting for hours for coatings to dry has become a thing of the past, and so has the emitting of toxic fumes and worrying about environmental violations. In place of the traditional methods, surfaces are cured in just seconds under ultraviolet light, and the resulting finishes have a lifespan that is much longer than the traditional methods by years.

The transition is not happening unintentionally. UVLACK, a particular UV coating cured through ultraviolet light technology, is reshaping the surface protection approach of the industries. The technology caters to automotive dashboards, furniture finishes, and the likes, and the manufacturers are getting what they have longed for—a dream come true in the form of curing speed that is not only lightning-fast but also very durable and eco-friendly.

The figures back up the claim. A pipe manufacturer, for instance, reduced the VOC emissions from its production process by over 154,000 pounds per year just by switching to UV coating technology. This is not only a positive impact on the environment but also a business transformation that lowered their costs by $1.2 million per year and at the same time increased production by 50%.

Introduction to UVLACK

Consider UVLACK as a coating technology that has finally been able to meet the modern manufacturing demands. The main difference between UVLACK and other conventional coatings is that the former uses photoinitiators—chemical compounds that react when exposed to UV light—while the latter ones cure through evaporation or heating. This results in instant polymerization, turning liquid resin into a very hard protective layer in just a few seconds.

The technology’s main attraction is not only the quickness of it. The UV resin is composed of oligomers which are responsible for the basic characteristics such as flexibility and chemical resistance, monomers that control viscosity, and photoinitiators that induce the curing reaction. This exact mixture gives the manufacturers the power to tailor the coatings to their needs, be it a requirement for scratch resistance for auto parts or moisture protection for electronics.

The technology is observed by the market. The LED UV-curing technology now has a lifespan of 20,000 hours whereas traditional mercury lamps last only 1,000 hours with 40% less operational cost. That is the reason why the industries from packaging to aerospace are switching over.

Understanding UV Resins

UV resins represent a fundamental shift in coating chemistry. Rather than waiting for solvents to evaporate, these formulations rely on photochemical reactions that happen at the speed of light—literally.

Composition of UV Resins

An UV resin system’s backbone naturally consists of three vital parts—the main component being oligomers that determine the cured film’s main characteristics: hardness and flexibility; the next, monomers functioning as reactive diluents for viscosity control and adhesion improvement; and last but not the least, photoinitiators that catch UV light and, consequently, start the polymerization process.

Today’s and future’s compositions usually use urethane, epoxy, and polyester acrylates as oligomer bases. Each of these has its characteristics. The main advantages of epoxy acrylates are excellent adhesion and very fast curing—thus ideal for wood and printed circuit boards. On the other hand, urethane acrylates are not very hard but are resistant to abrasion—thus very good for flooring and flexible packaging.

The real magic of invention comes when producers mix these parts. For instance, a furniture manufacturer could use urethane acrylates with certain monomers to develop a coating that is scratch-resistant and still allows the wood’s natural feel. Conversely, an electronics firm might choose epoxy acrylates to get the best moisture protection on circuit boards.

How UV Resins Work

The curing process is quite simple on the surface but at the same time very sophisticated. Coated surfaces get UV rays and the photoinitiators present in the coating take up the energy and produce free radicals or cations, which in turn, ignite the polymerization of the entire liquid coating with great rapidity.

This process is 1-2 seconds, and it results in the formation of cross-linked polymer networks. The “on-demand” curing option gives the manufacturers exact control—they are able to take enough time to place components before the cure is activated by means of UV exposure.

The polymerization reaction makes the surface hard immediately and, in this way, avoids the dust contamination problems that air-dry coatings are subject to. Production lines remain running, quality control is better, and there is a significant increase in throughput.

The Advantages of UV Coating

Here’s where UVLACK separates itself from every coating technology that came before it.

You may like: Food app developing apps

The speed factor has the last word in the conversation. UV coating lines for tubes are capable of producing at a speed of 1,000 feet per minute, whereas water-based systems are still waiting for evaporation to take place. For producers, this means that they can finish their work within the deadline which would have been a dream with the conventional coatings.

High levels of VOC are discharged during the curing of the thermal coatings; on the other hand, the UV coatings are usually low in VOC as they are based on the non-solvent technology. The VOC emission of UV systems is generally less than 1% of the total volume – some products even do not contain VOC at all. It is not just about marketing hype, but rather the actual reduction in environmental impact that helps companies comply with the ever-tightening regulations.

The toughness is a trait that is highlighted as well. The fast-moving curing process forms a tough and abrasion-resistant, and at the same time a very strong surface that is resistant to scratches, chemicals, and many environmental factors. The manufacturer doesn’t have to worry about the product losing its attractiveness too soon; the warranty claims and customer complaints will also decrease.

Energy efficiency is becoming a greater concern. LED UV systems use up to 70% less energy than the traditional mercury vapor lamps, and their lifespan can even go up to 50,000 hours. That means considerable savings on electric bills and replacement of lamps.

UVLACK’s Unique Selling Points

What makes UVLACK specifically stand out in the crowded UV coating market?

Durability and Resistance

The cross-linked polymer network present in UVLACK is a combination of factors that make the product long-lasting, and they have added to the visuals by using UV blocker in the mixture which prevents fading due to sunlight exposure. The combination of these factors, of course, significantly increases the life of the coated items.

Testing on UVLACK proved that scratch and chemical resistance were retained and it also offered good protection against stains, oils, and household chemicals. This is a great benefit for furniture manufacturers as their product, i.e., tables and cabinets would still look fresh and new even after years of daily use. For the automotive suppliers this would mean interior parts that can actually survive the harshest conditions inside a car—which are extreme temperatures, UV radiation, and also constant human interactions.

Environmental Benefits

The ecological argument in favor of UVLACK is not limited to its very low VOC emissions only. The air-pollutant-free mixture lessens the pollution in the atmosphere, negligible in its impact when it comes to the production and transportation, and does not use much energy in production thus the environment is protected.

UV coatings are eco-friendly and they cut the VOC emissions by up to 90% when compared to the traditional solvent-based. They consume the least energy in curing when compared to heat-based curing methods. UV coatings are non-flammable, have no solvents, and are free of VOCs and hazardous air pollutants, which makes them REACH compliant with no PFAS or heavy metals.

Compared to thermal coatings, UV coatings produce much less waste as they can be applied very accurately while using only a small amount of material which leads to minimal overspray. This leading waste reduction to saving of resources and lowering of disposal burdens thus creating a really circular manufacturing approach.

Applications of UVLACK in Various Industries

The versatility of UVLACK becomes clear when you examine specific industry applications.

Automotive Sector

UVLACK finds its most common application in the automotive industry where it is extensively used for the finish of dashboards, bumpers, trims and other exterior parts. The scratch-resistant properties of the product contribute to the retention of the surfaces’ elegant appearance despite them being used constantly and exposed to sunlight, plus the color depth and gloss are enhanced thus premium looking cars are created.

Top producers value UVLACK for assembly applications as well. It adheres fabric interior parts, plastics, electronics, and headlight units; at the same time, the rapid curing avoids the common glue-related bottlenecks of production.

Furniture Manufacturing

Wood finishing is one of the most popular applications of UVLACK, giving the wood a natural look while at the same time protecting it from scratching, spilling, and UV radiation. UVLACK is acclaimed by furniture manufacturers for its ability to bring out the natural grain patterns while at the same time providing the long-lasting safety of the coating that penetrates a little bit into the wood fibers for excellent adhesion.

Water-based UV coatings offer the best resistance to boiling water and fantastic chemical resistance for kitchen cabinets and furniture that often get exposed to cleaning products and spills. Professional and durable surfaces for flooring, cabinets and decorative furniture obviate the need for yearly maintenance and retain their good looks for years.

Electronics Industry

Electronic protective coating gives devices a shield against scratches and water. Conformal coatings take care of PCBs by covering delicate parts, wire tacking, and bonding displays.

The UVLACK coating is used in mobile phone cases, keyboards, and other gadgets to avoid fingerprints, scratches, and daily use effects while keeping attractive finishes. Besides, the coatings resist environmental factors such as humidity up to 95% relative humidity and temperature extremes from -40°C to 150°C.

Comparison with Traditional Coatings

Put UVLACK head-to-head against conventional coatings, and the differences are striking.

While traditional coatings can take hours or days to cure, UVLACK curing is done in seconds. The speed advantage directly corresponds to the increased production capacity. One manufacturer increased speeds from 100 feet per minute to 150 feet per minute—a 50% boost—just by switching to UV technology.

The air pollutants produced by the solvent-based coatings are harmful VOCs that contribute to air pollution. On the other hand, UV coatings are usually made of 100% solids and thus, release little to no VOCs. This results in better air quality and safer working environments.

Thermoset coatings need curing at high temperatures and thus, are energy consuming and costly due to prolonged heating times that reduce efficiency. UV coating is a faster and energy-efficient alternative while maintaining similar or even superior performance characteristics.

The difference in the finish quality can be easily seen. UVLACK gives off high-gloss, scratch-and-chemical-resistant surfaces that won’t fade or crack. Traditional coatings, on the other hand, often yellow over the years, become brittle, or show poor chemical resistance—issues that UVLACK has eliminated.

Case Studies: Success Stories with UVLACK

Real-world results validate UVLACK’s promises.

The move to UV coating by the pipe manufacturer resulted in a drastic reduction of 154,000 pounds of VOC emissions every year, besides gaining a yearly cost saving of $1,277,400. Along with that, the plant managed to hike its production speed up to 50%, the rate of which was changed from 100 feet per minute to 150 feet per minute. This wasn’t a small pilot project—it was a full-scale transformation of the coating operations.

A leading North American tube producer had to deal with coating operation difficulties caused by water-based systems. They were able to eliminate VOC emissions and cut down on remediation costs after switching to UV coating technology, which also allowed them to reach speeds of up to 1,000 feet per minute. The UV process made capital more efficient because it produced more and the production cycles were faster.

As part of their global environmental strategy, Armstrong World Industries has installed UV/EB technology worldwide and it is the last step in their overall environmental strategy. Columbia Forest Products, along with R&D Coatings, created a UV-curable stain that’s 100% solids with no solvent; thus, VOC regulation concerns are eliminated entirely.

These are not only wins in the area of technology but also the application of technology as the industries across manufacturing sectors are reporting similar transformations—faster production, lower costs, better environmental compliance, and superior product quality.

Future Trends in UV Coating Technology

The UV coating revolution is just getting started.

Researchers are coming up with new coating materials that not only have self-healing properties but also offer the option to choose matte, gloss, or texture finishes. Moreover, a car dashboard that can automatically repair small scratches, or furniture that can still look like new after years of use is not only dreamt of but also possible now.

To mention the trends that are key in this area, there are environment-friendly UV coatings that are made from bio-based materials and hence have a lower environmental impact, digital UV printing that is integrated with short-run projects for customized purposes, and smart packaging applications that are utilizing textured or spot UV for interactive sensory experiences. The picture of the coatings which are enhanced by nanotechnology shows the increase in their resistance and longevity through the utilization of nano UV formulations.

Usage of LED UV-curable coatings in the automotive and consumer electronics sectors has gone up by 25% as a result of the precision and the compatibility with temperature-sensitive materials. The rate of adoption will only increase further as LED technology gets more affordable and versatile.

The drive towards sustainability is still on, and it is getting stronger. The bio-based specialty acrylates and methacrylates offer not only high quality and technical performance but also have reduced carbon footprints. With the world becoming stricter and stricter in terms of regulations, these green formulations will not simply be a standard for the premium segment but will cover the whole market.

The technology around smart coatings is the next level. UVLACK products, tomorrow, may change hues based on heat, keep on giving feedback about surface conditions in real-time, and even connect with IoT systems to issue predictive maintenance notifications.

Conclusion

The coating industry needed this revolution. For decades, manufacturers accepted trade-offs—speed or quality, durability or environmental responsibility, performance or safety. UVLACK proves those trade-offs were never necessary.

The evidence speaks clearly:

- Instant curing eliminates production bottlenecks and increases throughput by 50% or more

- Environmental benefits cut VOC emissions by up to 90% while achieving substantial energy savings

- Superior durability extends product lifespans and reduces warranty claims

- Versatile applications span automotive, furniture, electronics, and beyond

The market for UV-curable coatings is indeed on an upward trend, primarily driven by the strictness of environmental regulations and the need for eco-friendly solutions. Firms that implement the UVLACK method now are likely to gain benefits that will only get bigger with time.

Whether it is furniture making, car part producing or electronic devices protecting, UV coats bring real pluses against the old techniques. The big question is not whether to go for UVLACK, but rather how fast you are willing to do it in order to gain those benefits.

The future of coating tech is now, one second of UV light curing at a time. Are you set to disrupt your manufacturing line?